Lyndall Brakes Oversized 13" Smooth Cut Front Rotors

- Prix habituel

- €769,90

- €769,90

- Prix habituel

- Prix soldé

- Prix unitaire

- / par

Impossible de charger la disponibilité du service de retrait

Lyndall Rotors

Our full-floating rotors are CNC machined to exact tolerances right here in the USA. Lyndall rotors are meticulously designed and tested to ensure maximum performance in the most extreme environments and conditions known to powersports. We are so confident in our choice of design, materials, and method of manufacturing that we guarantee our rotors will not warp (when used exclusively with our organic brake pads).

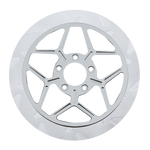

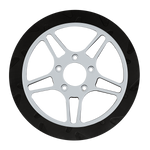

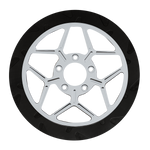

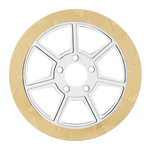

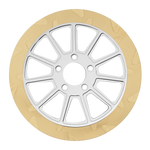

Our lug-drive rotors feature a highly advanced three-piece design:

- Outer friction ring (wear surface)

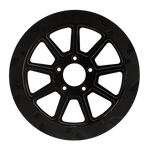

- Inner carrier center (aesthetic portion)

- Helical retaining ring that securely fastens the friction ring to the carrier center

Our rotors have a 5 x 3.25" bolt pattern, excluding Enforcer, Switchblade, Limited, Pan America, and V-Rod rear.

Enhance Aesthetics

Experience unparalleled bike customization with Lyndall rotors' black and gold finishes. While the allure of these finishes is undeniable, it's important to note that they do not improve brake performance and over time the surface finish will wear. But the gas slots and edges of the rotor that do not make contact with the brake pads will not wear.

Preserve Lyndall Rotors with Z+ Brake Compound

To maintain the appearance of your black or gold rotors, we advise utilizing our Z+ brake compound. This compound helps safeguard the finish from gradual wear, however after approximately 5,000 miles even with the Z+ brake compound will wear the finish off of the rotor. Remember, the gas slots and rotor edges, untouched by the brake pads, will retain their finish over time. Watch the video below for more details.

Optimal Performance with Gold+ Brake Compound

For riders who prioritize both performance and aesthetics, our Gold+ brake compound is the ideal choice. Designed to prioritize braking effectiveness, this compound removes the finish from areas that engage the brake pads, while still delivering exceptional friction rating. This pad leaves a nice contrast look of machine finish and the original gold or black color in the gas slots of the rotor.

Lyndall Bow-tie rotors stand out among their counterparts for being remarkably lightweight and having superior outgassing capabilities, boasting half the weight of stock rotors. These qualities translate to enhanced rider control through decreased rotating mass, while the gas slots and windows efficiently prevent brake pad glazing. Moreover, our Bow-tie cut friction rings are engineered to minimize the contact surface between the brake pads and the rotor, thereby increasing clamping force per square inch. This intensification in friction empowers riders with a distinctly perceptible brake bite, solidifying an altogether more responsive braking experience.

The reduced weight of Lyndall Crown cut rotors enhances rider control by minimizing rotating mass, while the incorporated gas slots effectively outgas debris and gasses generated during friction, preserving the rotor's integrity against brake pad wear and aiding in cooling.

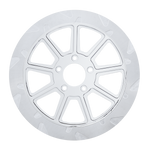

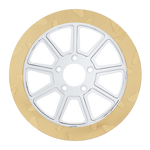

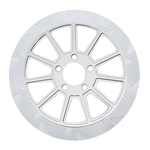

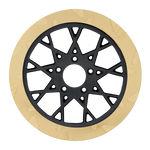

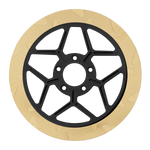

Lyndall Smooth cut rotors boast a timeless aesthetic that seamlessly integrates with any bike design. Renowned for their exceptional heat sink abilities, these rotors ensure braking system stability even under the most demanding braking scenarios. This friction ring design is particularly favored by racers who push the braking limits to the extreme.

Description

13” rotors require relocating your calipers, we recommend switching to radial mount calipers. The brackets can also be used with aftermarket four and six piston calipers, or 2018+ HD Softail calipers with caliper relocation brackets

Some stock HD Brembo calipers for touring models require modification to prevent clearance issues between the caliper body and rotor carriers. The calipers require modification; click here for more details.

For pre 2000 HD models with original wheels and Timkin bearings, order our adapter ring to narrow the inner diameter of the rotor to 1.985”.

Contact us if you have any questions or concerns.

Lyndall Rotors

Our full-floating rotors are CNC machined to exact tolerances right here in the USA. Lyndall rotors are meticulously designed and tested to ensure maximum performance in the most extreme environments and conditions known to powersports. We are so confident in our choice of design, materials, and method of manufacturing that we guarantee our rotors will not warp (when used exclusively with our organic brake pads).

Our lug-drive rotors feature a highly advanced three-piece design:

- Outer friction ring (wear surface)

- Inner carrier center (aesthetic portion)

- Helical retaining ring that securely fastens the friction ring to the carrier center

Our rotors have a 5 x 3.25" bolt pattern, excluding Enforcer, Switchblade, Limited, Pan America, and V-Rod rear.

Enhance Aesthetics

Experience unparalleled bike customization with Lyndall rotors' black and gold finishes. While the allure of these finishes is undeniable, it's important to note that they do not improve brake performance and over time the surface finish will wear. But the gas slots and edges of the rotor that do not make contact with the brake pads will not wear.

Preserve Lyndall Rotors with Z+ Brake Compound

To maintain the appearance of your black or gold rotors, we advise utilizing our Z+ brake compound. This compound helps safeguard the finish from gradual wear, however after approximately 5,000 miles even with the Z+ brake compound will wear the finish off of the rotor. Remember, the gas slots and rotor edges, untouched by the brake pads, will retain their finish over time. Watch the video below for more details.

Optimal Performance with Gold+ Brake Compound

For riders who prioritize both performance and aesthetics, our Gold+ brake compound is the ideal choice. Designed to prioritize braking effectiveness, this compound removes the finish from areas that engage the brake pads, while still delivering exceptional friction rating. This pad leaves a nice contrast look of machine finish and the original gold or black color in the gas slots of the rotor.

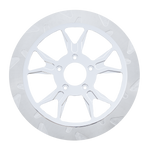

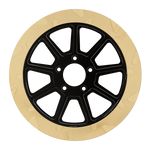

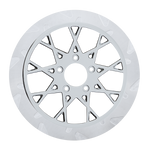

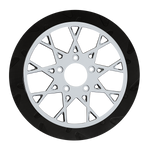

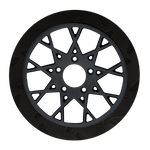

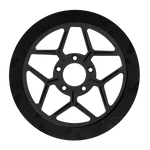

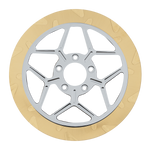

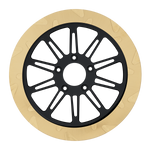

Lyndall Bow-tie rotors stand out among their counterparts for being remarkably lightweight and having superior outgassing capabilities, boasting half the weight of stock rotors. These qualities translate to enhanced rider control through decreased rotating mass, while the gas slots and windows efficiently prevent brake pad glazing. Moreover, our Bow-tie cut friction rings are engineered to minimize the contact surface between the brake pads and the rotor, thereby increasing clamping force per square inch. This intensification in friction empowers riders with a distinctly perceptible brake bite, solidifying an altogether more responsive braking experience.

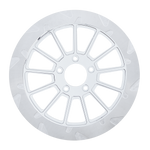

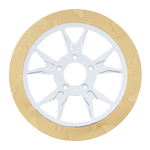

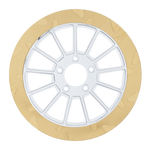

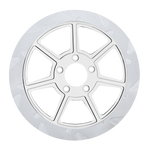

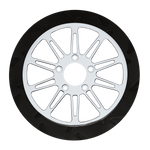

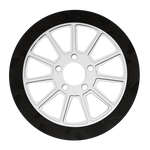

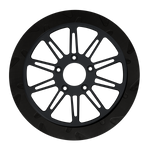

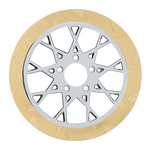

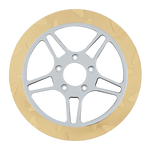

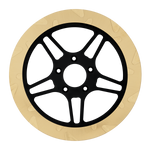

The reduced weight of Lyndall Crown cut rotors enhances rider control by minimizing rotating mass, while the incorporated gas slots effectively outgas debris and gasses generated during friction, preserving the rotor's integrity against brake pad wear and aiding in cooling.

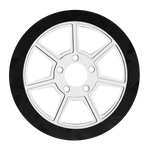

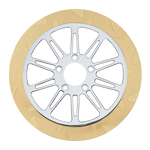

Lyndall Smooth cut rotors boast a timeless aesthetic that seamlessly integrates with any bike design. Renowned for their exceptional heat sink abilities, these rotors ensure braking system stability even under the most demanding braking scenarios. This friction ring design is particularly favored by racers who push the braking limits to the extreme.